Stability in an Unstable Climate: Why Real-Time Monitoring Matters

Climate change is reshaping the way industries think about stability. Unpredictable weather patterns and drastic temperature fluctuations have replaced the once-steady seasonal norms. For businesses operating in temperature-sensitive industries like pharmaceuticals, biotech, and specialty food, these fluctuations pose an even greater challenge: how do you ensure the integrity of your products when the environment around you has become so unpredictable?

The answer lies in real-time visibility and monitoring. In a world where every degree matters, delayed or fragmented monitoring isn’t enough. What’s needed is a system that alerts you instantly, wherever you are, giving you the ability to act before small problems become costly failures.

Why Real-Time Monitoring Matters More Than Ever

In today’s unpredictable climate, reactive monitoring simply isn’t enough. If a temperature excursion is only discovered after delivery, the damage is already done. Real-time solutions like Cryopak Connect Wi-Fi™ and Mirador™ flip that script — shifting cold chain from reactive to proactive.

The benefits extend beyond risk prevention:

- Reduced waste: Intervene before spoilage occurs.

- Improved efficiency: Centralized data means faster decisions.

- Enhanced reputation: Delivering safe, uncompromised products builds customer and patient trust.

- Sustainability support: By reducing product loss, you also minimize unnecessary re-production and shipping, contributing to greener operations.

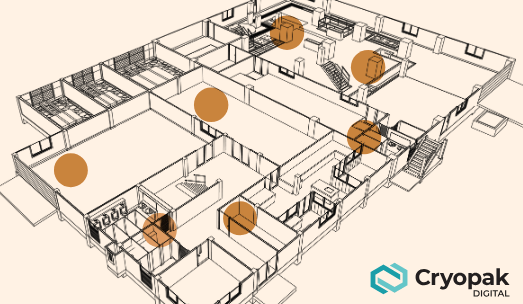

Temperature Mapping: A Foundation for Stability

Monitoring is only as effective as the environment you’re monitoring. That’s why Cryopak’s temperature mapping service goes hand-in-hand with real-time solutions. By identifying vulnerabilities within storage and distribution environments, mapping helps ensure compliance, product quality, and operational control.

Our service includes:

- Identifying cold and hot zones — Detect and correct problem areas before they compromise product safety.

- Monitoring humidity levels — Control and understand fluctuations that can affect sensitive goods.

- Real-time visibility — Track conditions continuously to support fast response and ongoing improvement.

- Optimizing storage conditions — Validate that all products remain within optimal, compliant ranges.

In a climate where weather and storage conditions can shift overnight, mapping builds a critical baseline of trust and control.

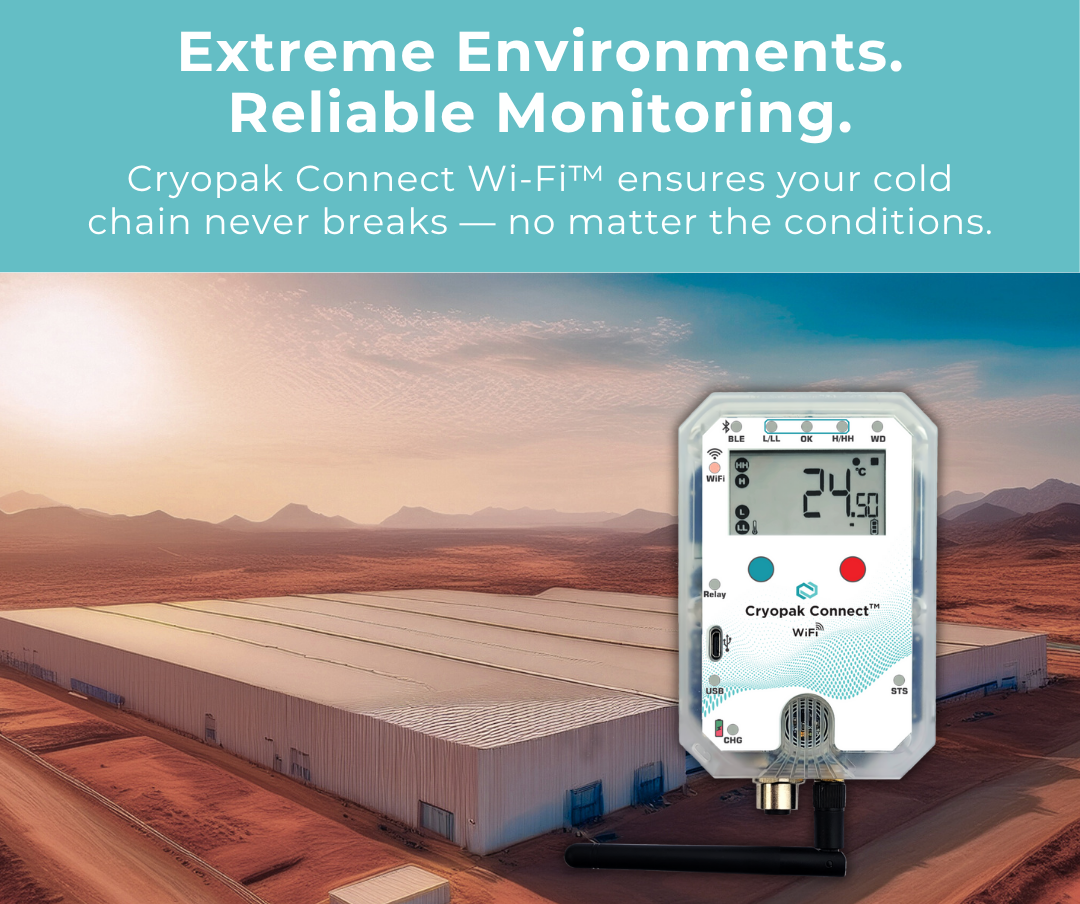

Cryopak Connect Wi-Fi™: Visibility Without Compromise

Cryopak developed Connect Wi-Fi™ to close those gaps and give businesses the confidence they need to manage their cold chain effectively.

Whether you’re dealing with 2–8°C controlled room temperature (CRT) ranges, frozen goods, or ultra-cold storage, Connect Wi-Fi™ is designed to deliver peace of mind through:

- Instant alerts for temperature or humidity excursions — so action can be taken before damage occurs.

- Live data access anytime, anywhere — because cold chain risks don’t keep office hours.

- Seamless integration into your existing workflows — minimizing disruption while maximizing oversight.

With real-time monitoring at your fingertips, your team gains the ability to protect product integrity, reduce costly spoilage, and maintain compliance without added complexity.

Beyond Devices: The Power of Mirador™

Monitoring devices are only one part of the solution. To truly protect your cold chain, you need a system that brings all your data together in one place. That’s where Mirador™, Cryopak’s cloud-based platform, comes in.

Paired with Cryopak Connect Wi-Fi™, Mirador™ provides:

- Continuous, real-time monitoring across all shipments and storage points.

- Centralized management — one dashboard for full visibility into your global operations.

- Audit-ready reports for regulatory compliance and quality assurance.

- Scalability to match your business growth and evolving product portfolio.

By eliminating blind spots and providing actionable insights, Mirador™ transforms raw data into a strategic advantage.

Peace of Mind in Every Degree

At Cryopak Digital, we specialize in cold chain validation services to help you meet regulatory requirements, improve risk management, and ensure the quality of your temperature-sensitive products — from storage through distribution.

Ready to upgrade your monitoring system? Contact us today to explore more.